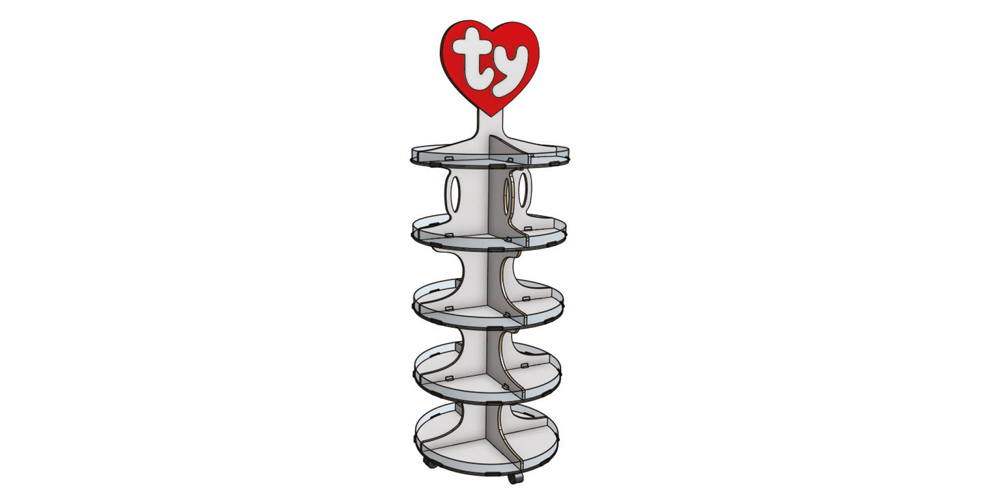

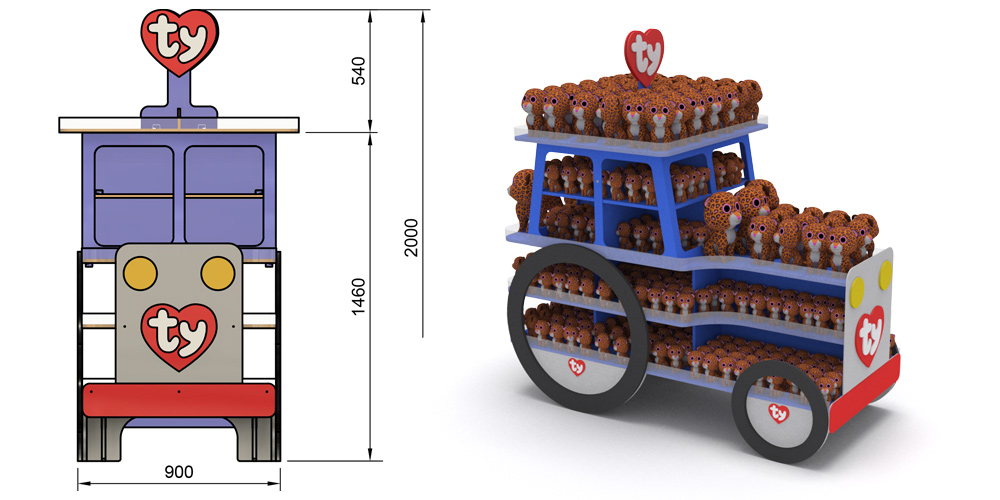

Crash Test - 24” Displayer

Problems and Solutions

Solution

Improved packaging + warning labels

Starting from November 2023:

- We are adding an extra layer of film to the bottom part of the pallet.

- We are securing the underline with brackets to the pallet

Starting from 2022:

- If there are unsecured boxes on top of the pallet, it is mandatory to label them with a sticker.

Solution

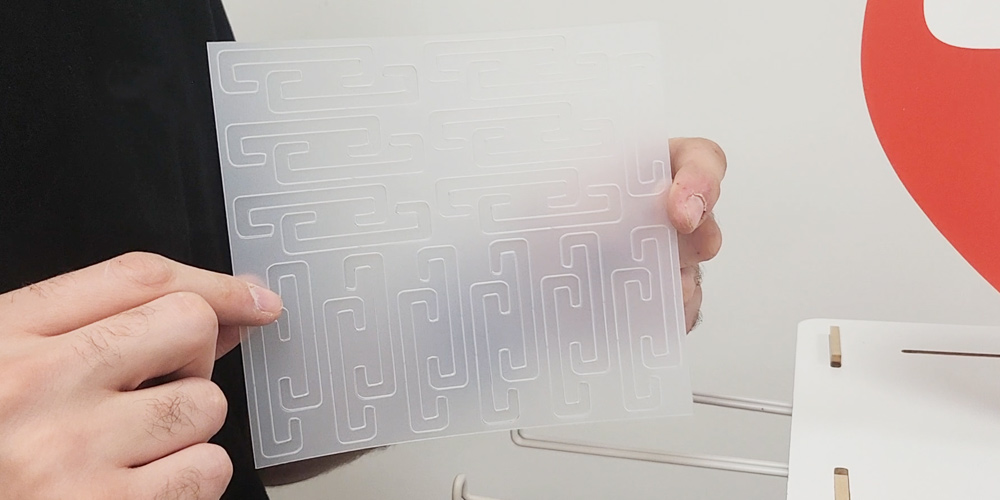

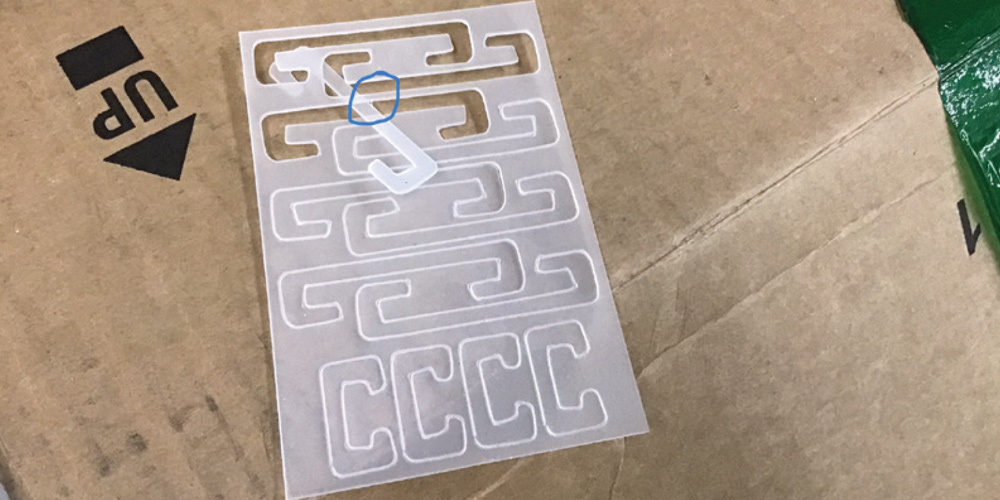

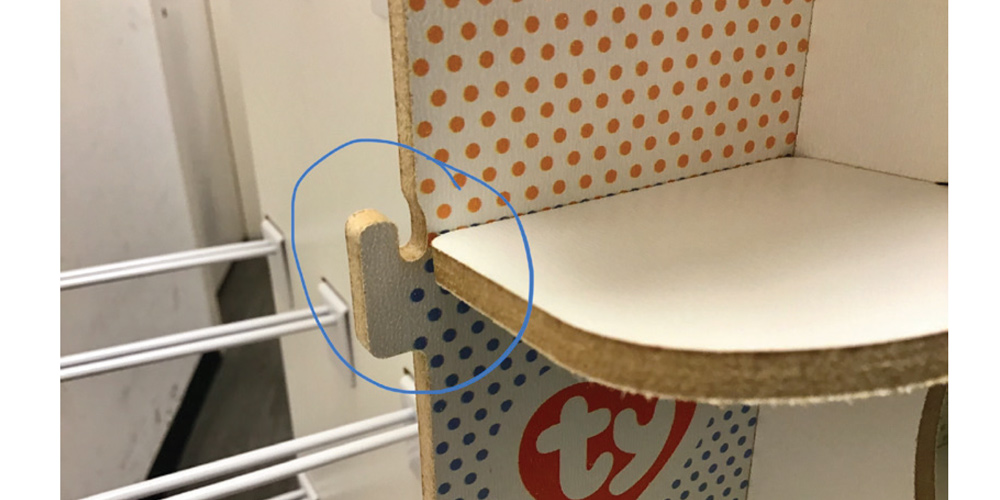

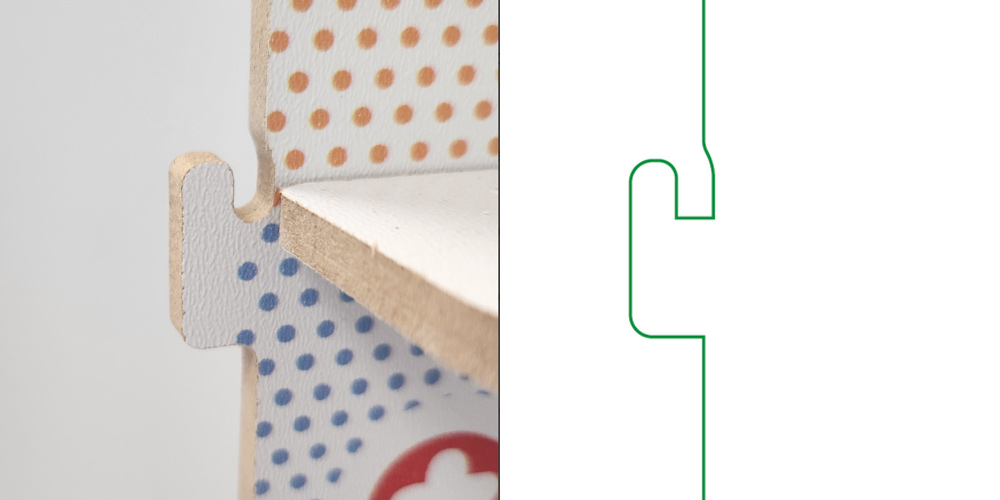

Modern c-clips and u-clips

Starting from 2022 we are manufacturing new C-clips.

- Flexible

- Cut-out

- “Bridges” for quick and convenient use.

C-clips and u-clips can be easily installed without any additional tools.

Problem

Spare c-clips and u-clips

24” Displayer assembly with regular sized items only IF all product is ready to be placed: 30-40 minutes

Suggested improvement: start to include a few spare c-clips and u-clips and not just the exact number needed to assemble.

Solution

We have added spare clips

Starting from November 2023:

- Add additional “C” clips.

- Add additional “U” clips.

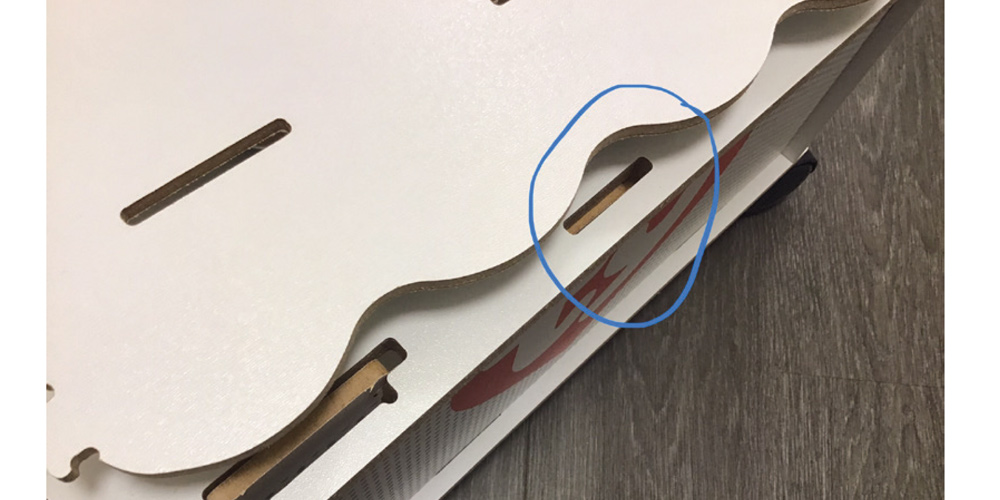

Problem

4-sided displayer – the side panels

“The side panels that hold the Balls from falling are a constant problem. The material they’re made of is too brittle and many times I break the bottom connecting hole just trying to get it on its post. Please have all the tabs completely punched out before placing these in the rack box. More time wasted at the build time.”

Problem

4-sided displayer – the base

“The 4 sided takes me about and hour fifteen to an hour and a half. (That’s loaded). I use a Mallot also and it is very loud. The mini boo clips take longer to zip open and load. The base doesn’t always go together properly especially if anything is at all chipped. If the parts are wet which I’ve had a couple that came in where the box had moisture, the panels swell and will not fit together. “

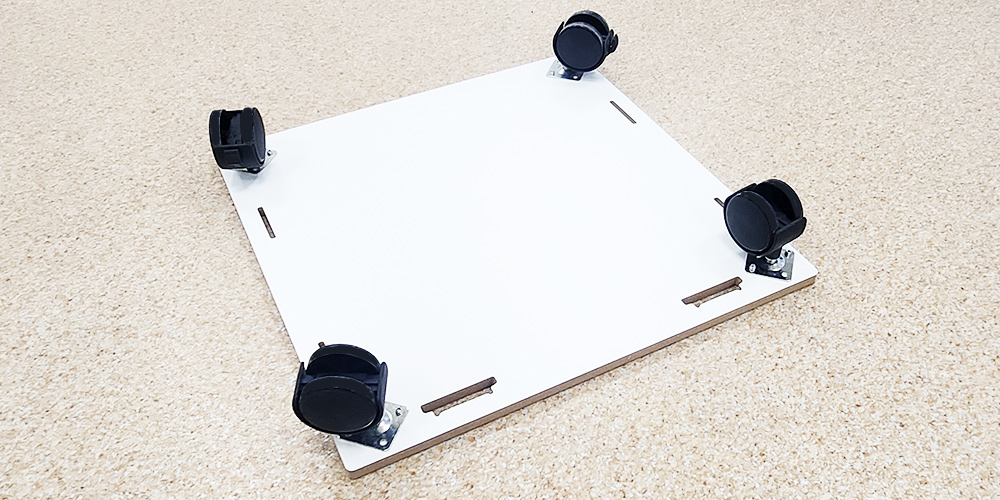

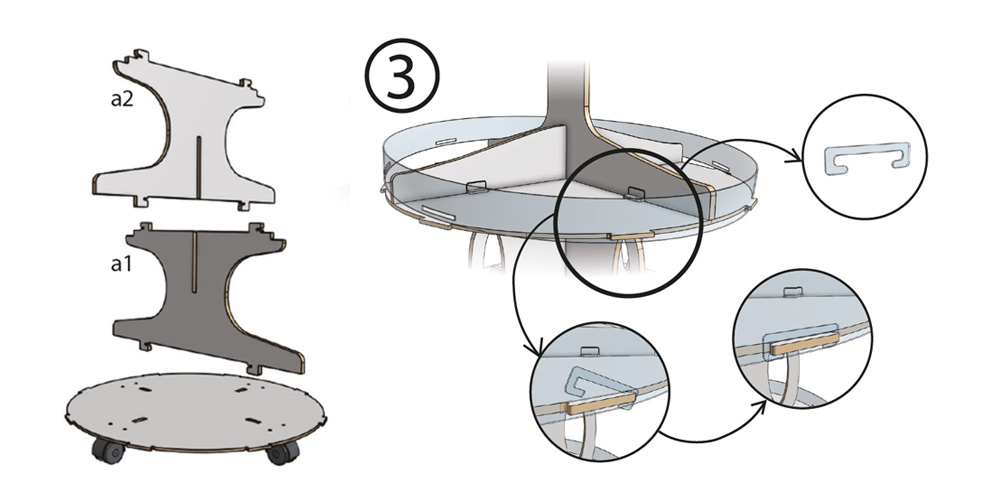

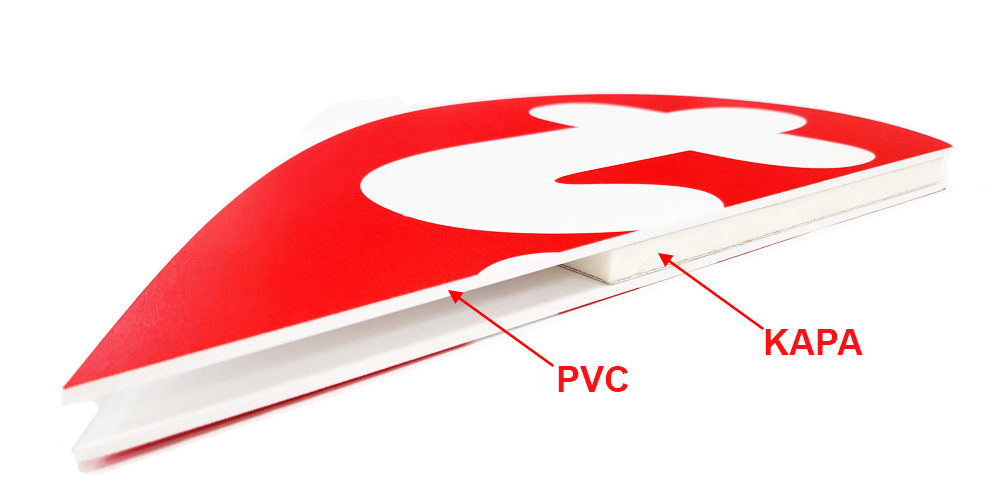

Solution

Proper installation

The stand base (box) is assembled very easily. It is necessary to snap the fastenings. The process is shown in the video.

Solution

Proper installation

Starting from summer 2023:

- We added additional pieces of foam.

- We added extra cardboard protection for the most vulnerable parts.

- We started using a new type of rivet for better wheel fixation and to prevent base damage.

The video below shows the crash test of the stand. Even after falling from approximately 2.5-3 meters (the height of a second-floor residential building), the stand remained intact with only minor damage.